From the time of the first vision correction devices to the present day

- Mineral glass

- Reading stone

- Plastics for the production of spectacle lenses Types of organic materials

- CR-39

- Organic materials with an average refractive index (1.53–1.59)

- Organic materials with high and ultra-high refractive index values (1.59–1.76)

- Polarizing materials

Historians call the invention of glasses the fifth most important discovery of mankind, which began with the use of fire and the creation of the wheel. Thanks to glasses, millions of people could have good vision, despite various types of ametropia. The most important component of corrective glasses is the lens, which appeared in the form of magnifying glasses even before glasses. Over the centuries, as science and technology have advanced, lenses have undergone major changes, both in terms of design and the materials used to make them. Let's look at the evolution of materials for spectacle lenses.

Custom Lenses: Progress Continues

The first individual lenses appeared in the early 2000s in the progressive lens category from Carl Zeiss and Rodenstock and became a real breakthrough in vision correction. Previously, traditional progressive lenses were made from factory semi-blanks, designed to produce lenses of several optical powers and averaged and accepted as standard frame fit parameters. Patients had to adjust, and some had problems adjusting. Individualization of spectacle lenses has become possible thanks to the advent of Free Form technology, powerful computers and calculation programs, and automatic equipment that allows the production of complex surfaces with high precision. The high-precision surfaces of these lenses help reduce some of the higher-order aberrations that affect field of view size and image contrast in low light conditions. As a result, each lens is manufactured according to the parameters of a specific patient, which ensures high quality vision and rapid adaptation.

The number of individual parameters taken into account gradually increased. Initially, these were specific data on the prescription and fit of the frame (the so-called wearing parameters), monocular PD values, then they were added to the shape of the frame, the usual position of the head and the characteristics of the patient’s visual activity, taking into account the dominant eye and anisometropia. Some designs take into account the most important visual distance when wearing progressive lenses, the anatomy of the eye - such as the location of its center of rotation, and even whether a person is left- or right-handed.

Somewhat later, individual single-vision lenses appeared, the calculation of which takes into account wearing parameters - monocular PD values, pantoscopic angle of the frame, bending radius of the frame frame, vertex distance, that is, all the parameters on which the actual formation of the refraction of the vision correction device depends. Some manufacturers, along with these indicators, take into account additional data that makes it possible to more accurately characterize the individual characteristics of the visual system of the glasses user: for example, the relationship between head and eye movements, the anatomy of the eye - the distance to the center of rotation of the eyes, etc. In individual design calculations, you can enter the distance required by the patient for working close or at intermediate distances. Initially, individual single-vision lenses were recommended for the correction of high degrees of ametropia and astigmatism, which in these cases made it possible to achieve optimal vision in any direction of view without peripheral aberrations at the edges of the lens, with an increase in the field of clear vision, and improved image contrast. Adaptation to new glasses with individual lenses is easier and faster.

Lens coatings

Most modern glass is made from polymers and has an aspherical design. This means that they themselves scratch and create glare. Manufacturers managed to mitigate these shortcomings with the help of coatings. Applying protective layers to lenses gives them amazing properties.

Types of coatings:

- Hydrophobic

. Located at the top. They make the surfaces of the lenses smooth, which makes it difficult for water and dirt to accumulate on them.

- Anti-reflex brightening

. Remove glare and make lenses more transparent. Thanks to them, the glasses become much more comfortable to wear.

- Metallized

. Block electromagnetic radiation from computers and TVs.

- Strengthening

. Applied to polymer materials to make them scratch resistant.

There is no point in applying a UV blocking coating to most eyeglass lenses. After all, the materials from which they are made do not themselves allow ultraviolet waves to penetrate the eye.

By the way, don't confuse a darkening coating with one that blocks UV rays. The presence of tint does not guarantee that sunglasses protect your eyes from ultraviolet radiation.

Difficulties in selection and appointment

The cost of individual lenses is much higher than the cost of standard lenses, which is explained by complex methods of selection, calculation and manufacturing. If, when choosing a new frame, a buyer can evaluate its design, color scheme, workmanship, fit and consistency with the image, then it is much more difficult for him to evaluate the quality and properties of individual lenses at the time of choice. In practice, at first glance for inexperienced glasses users, individual lenses are no different from ordinary ones - the same circle (or oval) made of transparent plastic. Today, in order to talk about these lenses and explain their benefits, optical consultants use various illustrations, demonstrators, and even virtual reality glasses that allow the client to evaluate the quality of vision in glasses with standard and individual lenses.

Individualization of lens designs required increased accuracy in measuring centering parameters, which cannot be provided by a conventional ruler with a marker or even a pupillometer. If measurements are taken incorrectly, as well as if parameters are violated when assembling glasses, the quality of vision in glasses with individual lenses can become even worse than with standard ones. To correct the situation, video alignment devices and terminals were created that allow achieving the required level of measurement accuracy; In addition, they are convenient to use for consultation when choosing lenses and frames. More affordable devices are available on the market - attachments for iPad or other tablet computers, which make it possible to measure centering and wearing parameters quickly and with high accuracy.

Taking into account individual parameters for the manufacture of lenses contributed to a more active involvement of patients in their choice: a person must answer a number of questions, indicate the most important features of professional activity and hobbies. As a rule, he fills out a questionnaire in electronic or paper form, on the basis of which the program determines the most significant visual areas, and therefore the lens design. Creating a visual profile of a client is already possible via the Internet.

We asked representatives of companies that distribute spectacle lenses from the world's leading manufacturers, as well as a domestic company that produces spectacle lenses, to answer a number of questions about individual lenses offered on the Russian optical market:

- What are the latest custom progressive lenses available in your product range? What individual parameters are taken into account when selecting and manufacturing them?

- What are the latest custom single vision lenses in your product portfolio? What individual parameters are taken into account when selecting and producing them?

- Who should recommend custom lenses – patients with high ametropia, astigmatism, anisometropia, or all potential glasses users?

- What tools and devices do you need to use when selecting lenses and taking the necessary measurements?

We present to your attention the responses received.

Hoya Rus lenses,

distributor of Hoya Vision Care products

- Hoya Vision Care offers four individual designs in its range of progressive lenses.

Hoyalux iD LifeStyle 3i are individual progressive lenses tailored to the user's lifestyle. When calculating them, the interpupillary distance, distance for working near, frame fitting parameters are taken into account, and one of three designs is selected, taking into account the different visual needs of the client: Indoor - design with an expanded zone for near and medium distances, Outdoor - design with the widest zone for distance , Urban – balanced design. Easy and quick adaptation is facilitated by the technologies used, such as iD FreeForm Design - a technology for creating a double integrated progressive design, Binocular Eye Model - a technology for assessing the joint work of the eyes, Stable View Enhancer - a technology for reducing dynamic distortion and thereby the floating effect, View Xpansion - a technology for reducing lateral aberrations and thereby expanding the field of view. For prescriptions with different corrections of two eyes, Binocular Harmonization is used - a technology to reduce the negative impact of unwanted prismatic effects horizontally and vertically. The presence of four progression corridors of different lengths does not limit the client’s choice of frames.

Hoyalux iD MyStyle V+ are individual progressive lenses, the design of which is based on the specific visual needs of the client. To create the design, a special iDetifier program is used, which, in addition to the client’s current visual environment, takes into account the following individual parameters: prescription, previous vision correction (amount of prescription change, satisfaction with the previous lens design), interpupillary distance, distance for working near, frame size and its parameters wearing. A virtually unlimited number of custom lens designs are available. The same technologies are used in creating the design of the Hoyalux iD LiFeStyle 3i lenses. The lenses are manufactured with six progression corridors, with the iDentifier software also selecting the progression corridor. In addition, there is an additional option EyeGenius - for recipes with prismatic correction. This variation provides better integration of the prism prescribed in the prescription into the lens design, which significantly improves adaptation and visual fields during prismatic correction.

Hoyalux iD MySelf - new individual progressive lenses, in the production of which, in addition to all those listed in the Hoyalux iD MyStyle V+ lenses, two unique new technologies are used: 3D Binocular Vision - technology for reducing unwanted prismatic effects or prismatic imbalance between the right and left eye induced by the distribution of progression ; Thanks to this technology, the user can enjoy stable near vision with no floating effect; Adapt Ease technology expands the field of view near and at medium distances without negatively affecting the distance zone.

Hoyalux iD WorkStyle V+ – individual office progressive lenses. They are intended for indoor use. There are three designs to choose from to suit users' visual needs and workspace: Close - for those who require precise, clear close vision while being able to see objects up to 1m away; Screen – mainly intended for those working at a computer, provides a view of up to 2 m; Space – in addition to being used at a desk, it makes it possible to move around the room, providing a view of up to 4–5 m. The design of the lenses is calculated based on the interpupillary distance, the distance for working near, and the frame fitting parameters. iD Design, Binocular Eye Model, and “Balanced Vision Control” technologies are used for calculations. When the correction of the two eyes differs, the negative impact of the prismatic effect is reduced using Binocular Harmonization technology.

- Hoya Vision Care's range of individual single vision lenses includes Nulux iDentity V+. They have an asymmetrical design; before production, the joint work of the eyes is analyzed using the Binocular Eye Model. When calculating lens design, the interpupillary distance and frame fitting parameters are taken into account.

- Individual progressive lenses provide the most comfortable vision for any user, especially when using them for near and medium distance vision. But such lenses are especially needed by clients with high degrees of refractive error and the presence of astigmatism. They are also suitable in case of non-standard interpupillary distance (small or large, with asymmetry), large addition, as well as choosing a non-standard fitting frame.

- Any vision correction requires adherence to an optometric protocol to ensure that the client has clear vision at all distances. But enjoying your clear vision with glasses is only possible if the glasses are positioned correctly in front of your eyes. To accurately measure alignment data to determine the position of the optical centers of lenses in front of the eyes, Hoya Vision Care recommends using the VisuReal Portable video alignment system. It consists of software installed on the iPad, an attachment on the iPad, and a special centering frame that fits onto the frame. The result of the measurement is not only accurate centering data, which is used both for ordering lenses and for installing them in the frame, but also the necessary fitting parameters: vertex distance, pantoscopic angle of the frame, bending angle of the frame frame, frame dimensions and the shape of the eyepiece or lens. Once measurements are taken, the results can be immediately transferred to the iLog lens ordering system with the click of a button. Working with VisuReal means both the accuracy of the measurements performed and the speed of obtaining the necessary data.

Rodenstock Rus,

distributor of Rodenstock products

- The latest development from Rodenstock and rightfully the best of its lenses in terms of vision correction capabilities is the Impression FreeSign PRO, released in 2021. In relation to the list of parameters included in the calculation of each individual lens, be it progressive, office, single vision or sports, the new lens uses technological innovations: individual distribution of the lens refraction according to the declared types of visual activity - more than a trillion different options; taking into account the measurements measured on the latest DNEye PRO scanner in addition to all lower and higher order aberrations of four biometric parameters of the eye, such as corneal topography data, anterior chamber depth, deviations in lens refraction and eye length, which are then included in the lens calculation. Thanks to the use of this biometric data, the lens is more closely matched than ever before to the type and degree of ametropia, and the image displayed on the retina is the clearest possible. The lenses are made from a new PRO 410 material with better protection against high-energy light and harmful ultraviolet rays, combined with Solitaire Protect Pro coating for noticeably higher transmittance and natural color rendering.

Any individual progressive lenses from the Impression family take into account the following parameters:

- lifestyle and visual priorities and preferences for the formation of individual design;

- measurement data on the DNEye PRO scanner (if available) – individual aberrations of the eye, including higher order aberrations;

- change in pupil size – pupillary reaction, taking into account photo- and mesopic vision;

- thanks to the use of EyeLT technology - separate prescriptions for distance and near with different values of the cylinder and its axis for astigmatic prescriptions, which is especially important for high additions and patients who have undergone eye surgery;

- individual landing parameters (PD; R/L; PT; CVD; FFA);

- individual insert in case of convergence pathology;

- individual working distance when selecting vision correction;

- individual working distance when using glasses;

- individual vertex distance when selecting vision correction;

- the ability to create the required base curvature for fashionable and large frames;

- frame shape and size;

- horizontal and vertical centering data;

- required optimizations (changing lens thickness along the edge, in the center, MDM, etc.).

For the newest Impression FreeSign PRO lenses, the values of such biometric parameters of the eye as corneal topography, anterior chamber depth, deviations in lens refraction and eye length are also included in the calculation and order.

- The most advanced individual single vision lenses in Rodenstock's portfolio continue to be the Impression Mono 2 lenses, nominated for the SILMO dʼOr back in 2006 and available in both a sports version and a design variant for driving glasses. In 2021, the optical power range of the Impression Mono 2 lenses, made of highly refractive materials, has been extremely increased and now ranges from -18.00 to +13.00 diopters.

When calculating Impression Mono lenses, the following parameters are taken into account:

- measurement data on the DNEye PRO scanner (if available) – individual aberrations of the eye, including higher order aberrations;

- change in pupil size – pupillary reaction, taking into account photo- and mesopic vision;

- thanks to the use of EyeLT technology - different values of the cylinder and its axis for astigmatism in the version with support for Plus accommodation;

- individual fit parameters (PD; R/L; CVD; FFA);

- individual vertex distance when selecting vision correction;

- the ability to perform the required base curvature for large, fashionable and sports frames;

- frame shape and size;

- horizontal and vertical centering data;

- required optimizations (changing lens thickness along the edge, in the center, MDM, etc.).

Lenses can be offered with or without accommodation support. If the lens contains an accommodation support function, “Plus” is added to the name of the lens: Impression Mono Plus 2. When ordering, you should also specify an addition value of 0.5 or 0.8 diopters.

- Traditionally, custom lenses have been recommended when choosing frames that have a non-standard fit on the face. However, later, given their increased field of view and its higher quality, with complex prescriptions, they firmly won their position as the best for patients with high ametropia, astigmatism, and anisometropia; This also includes cases where it is difficult to select patients after eye surgery, who are tall or overweight, as well as when it is impossible to follow the rules of the usual way of wearing glasses.

These lenses are designed for a patient who has the following qualities:

- does not compromise;

- counts only on the highest quality of performance;

- prefers individuality in everything;

- wants and can afford them.

- The best tool for measuring individual fit parameters is the ImpressionIST video centering system. Rodenstock is now offering the fourth generation of such units. Their list includes an Info terminal for the presentation of services, promotions and special offers, consultation and entertainment for clients waiting for reception or service, a device for consultation on lenses and frames - for showing frames from an aesthetic and cosmetic point of view, as well as full-face photographs for comparisons of frames or different angles, demonstrations of the thickness of different types of lenses, their coatings and colors, a 3D video centering system and a lens ordering system with its placement on the manufacturer’s server.

Simplified and less accurate measurements can be made using the Impression Tool, a set of measuring tools.

About the refractive index and lens cost

We must be frank and admit that the price of high-index lenses is higher than the price of standard index lenses with the same diopters. But perhaps these lenses will allow you to have excellent quality of vision, comfort and aesthetic appearance in your glasses. The choice of high-index material is determined by the recipe. Of course, if you want to wear only high-index lenses, this is your right, but when choosing a refractive index, try to take into account the opinion of a specialist

Remember that your eye care practitioner will be able to explain which high-index lenses are the best choice for your needs and budget. . However, there are exceptions. Therefore, be sure to check with specialists all the nuances - this will save you unnecessary financial costs and allow you to purchase really high-quality glasses and solve exactly your problems.

Essilor – Luys-Optics,

distributor of Essilor Group products

- The most high-tech lenses, taking into account not only the individual parameters of the client, but also the characteristics of the visual load of a modern presbyope, in the Essilor assortment are Varilux X Series. Their design combines the latest developments in multifocal lens personalization. With Varilux X Series 4D, a true revolution in personalization, lenses can be created taking into account additional individual parameters and characteristics such as the dominant eye, the position of the center of rotation of the eye, and the characteristics of the visual behavior of a particular user. The result is unrivaled vision quality and instant focusing in all conditions. Research has shown that gaze direction is determined by a combination of parameters such as head rotation and eye movement. According to the ratio of these parameters, all people can be divided into the following categories: eyemover (those in whom eye movements predominate) and headmover (those who turn their heads more often). If this ratio is taken into account in the lens design, the clarity of vision will be maximum while maintaining comfortable, habitual visual behavior. The most important part of the innovation is the dynamic three-dimensional measurement of the eye - the Eyecode option, which consists in determining the eye rotation center (ERC) in a three-dimensional coordinate system. The distances between the center of rotation of the eye and the cornea vary from person to person, and such differences are possible even with the same degree of ametropia, which confirms the uniqueness of each eye (similar to the uniqueness of fingerprints). Thanks to the Eyecode option, it is possible to produce a lens that perfectly matches the eye. Regardless of the degree of ametropia, the design of each lens will be calculated 5 times more accurately than a lens without the Eyecode option.

And another important thing: when processing an image, the brain gives priority to the information that comes from the dominant eye. In everyday life, it is the dominant eye that sees the target first. Thanks to the use of Dominant Eye technology in the manufacture of lenses, high visual acuity in motion and instant visual response are ensured. Instant response is an advantage, and safety is a consequence.

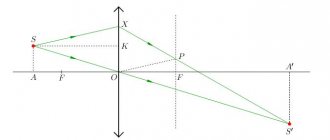

Features of the visual load of a modern presbyope include the need to work in multitasking conditions with frequent changes in the working distance within the length of an arm (in the range of 40–70 cm; Fig. 1). Xtend technology is used in the production of lenses, which improves the quality of vision, increases its acuity and users can clearly see all objects in this area in one direction of view. But that's not all. If you use special compact equipment, you can get even greater personalization, the so-called NVB code - a code for near visual behavior. NVB carries information about the glasses user's habit, such as shifting text to the right or left (sometimes called a sign of loterality), the preferred direction of gaze, the accepted distance of the text, and the usual ratio of eye and head movements when reading.

Rice. 1. Working distance, cm, within arm length for areas of eye strain

As a result, Varilux X Series lenses combine the most advanced technologies to provide the user with unrestricted vision within the arm's length while maintaining excellent distance, intermediate and near vision. And thanks to the use of Nanoptix technology in the manufacture of these lenses, there is practically no floating effect when moving the gaze (well known to owners of multifocal lenses of older generations), and Varilux X Series lenses are much thinner than lenses of other designs with similar parameters.

- Modern glasses users of any age want to get the highest quality vision without limitations, regardless of the degree of ametropia, and to have the opportunity to have a wide choice of frames of various configurations and designs. Essilor has developed the Essilor f-360° single vision lens, which provides high-resolution vision regardless of the direction of view. When creating a design and calculating the parameters of lens surfaces, a complex WAVE wavefront control system is used. The basis of this system is a detailed analysis of the passage through the lens not of an individual beam, but of the entire three-dimensional flow of light, the wavefront. Moreover, the analysis takes into account the work of the refractive media of the eye and its physiology. This significantly reduces refractive aberrations, including those of higher order. As a result, the image on the retina is much clearer and more contrasty. And thanks to the most precise digital (point-by-point) processing of lens surfaces using Advanced Digital Surfacing technology created by Essilor, such complex designs are possible. It is through the combination of design and the level of its implementation that users of glasses with Essilor f-360° lenses are provided with high-resolution vision. And of course, when calculating lenses, the individual parameters of their location relative to the user’s eyes are taken into account. It is possible to obtain high-quality vision in the most daring, even extreme positions:

- pantoscopic frame tilt angle from –5 to +25°;

- vertex distance from 5 to 22 mm;

- The bending angle of the frame frame is from 0 to 25°.

The user of glasses with Essilor f-360° lenses receives clear, contrasting vision regardless of the direction of gaze and the fitting parameters of the frame.

- Of course, first of all, individual lenses are needed for people with high degrees of refractive error, with astigmatism, for those patients for whom the slightest deviations from central vision are critical. Also, the resulting high quality of vision will be appreciated by those who have to work in low light conditions (for example, driving at night), and by clients who take a long time to adapt to new glasses. Users of contact lenses will also be grateful for the prescription of individual lenses (after all, they are used to seeing very clearly). In general, all clients who need vision correction and want to get the highest quality vision in any situation will appreciate the benefits of individual lenses.

- Taking into account the high technologies that are used in the manufacture of individual lenses, the complexity of calculating designs and the unique accuracy of their execution, we recommend marking the position of the pupil in the opening of the rim of the frame and all necessary measurements using video measuring systems. Essilor has such systems of varying levels of complexity, with a different set of available measurements (but the ability to determine basic individual parameters - the position of the pupil in the rim of the frame and the position of wearing glasses - is available in each of them).

Rice. 2. Premium Visioffice measuring system

In Fig. 2 presents the premium Visioffice measuring system. This measurement system, developed by a group of Essilor scientists, is based on collecting data on the visual habits of glasses users (head and eye movements), determining the interpupillary distance, installation height, and the distance from the center of rotation of the eye to the lens. All the necessary parameters can be obtained within a few seconds using the Eyecode option (already mentioned above). This option also takes into account the fit of the frame and the natural tilt of the head.

There are two more video measuring systems that are most in demand in optical shops - ETM and Eyeruler 2 (Fig. 3). Each of them has its own characteristics and advantages. For example, Eyeruler 2 is the most compact of all similar systems on the market, and ETM is a presentable device in the form of a tabletop mirror that can emphasize the special status of an optical shop that works with individual lenses. Both systems allow you to measure all the parameters needed to order and manufacture custom lenses.

Rice. 3. Video measuring systems ETM (left) and Eyeruler 2 (right)

In any case, the use of video measuring systems significantly reduces the likelihood of error, facilitates the work of the medical specialist and consultant, and also creates a unique impression for your client about high technology in the optical salon.

Glasses for you

- The company's product range includes a series of Camber progressive lenses with double progression (from 2021), that is, with a variable base curve on the front surface and using DRP calculation technology on the inner surface. New to the series - Camber S35 lenses for beginners. Other lenses in the series are described below.

Progressive Premium Camber Steady is a core product for 2021 - a versatile custom progressive lens with a balanced design suitable for both beginners and advanced users. These lenses are a unique combination of a variable base curve on the front surface and the latest Steady technology for digital calculation of the internal surface, resulting in the most advanced progressive lenses that are comparable in comfort to the patient with single vision lenses. The wearer of these lenses enjoys improved peripheral vision, unrivaled image stability even while moving, and the widest possible field of view at all distances.

Progressive Drive II - new for 2021 - individual progressive lenses with a night vision zone, designed for driver glasses. At the top of these lenses there is an additional optimized zone (4 mm above the installation cross, an additional diopter power of -0.25) to compensate for night myopia. They provide panoramic distance vision, complete absence of distortion and clarity of vision in areas necessary for the driver, such as the road, instrument panel, and mirrors. The lens design also provides a stable near zone and takes into account the vision in the most commonly used zones - the distance zone, as well as the distance zone with a focal length of 4 m.

When prescribing lenses, the following characteristics are taken into account: monocular PD values, frame parameters, base curvature, individual convergence characteristics, vertex distance, pantoscopic frame inclination and bend angle, individual working distance for near.

- The range of individual single vision lenses includes Mono Drive and Mono Premium. Mono Drive - lenses with a night vision zone in the upper part. In this zone there is an additional optimized area (4 mm above the installation cross, additional diopter power -0.25) to compensate for night myopia.

From February, the offer of Mono Premium 1.67 and 1.74 lenses will include the “esthete” option - a double aspherical design, which will allow achieving a minimum thickness in the center of lenses made using Free Form technology with maximum optical quality.

When calculating and manufacturing lenses, the following individual characteristics are taken into account: monocular PD values, frame parameters, base curvature, individual convergence characteristics, vertex distance, pantoscopic frame inclination and bend angle, individual working distance for near.

The characteristics of the patient’s visual activity, the presence of a dominant eye, whether the user of glasses is right-handed or left-handed are not taken into account, although based on anamnesis it is possible to offer the most optimal solution for the client, for example, choosing a design with wider zones for distance or near.

- Of course, individual lenses can be recommended to patients with high ametropia, astigmatism, and anisometropia, but in addition to the listed categories, they can be recommended to people who are sensitive to aberrations and have difficulty adapting to any changes in refraction, as well as to clients who choose large and strongly curved frames.

Adaptation to new glasses with individual lenses is easier and faster.

In some cases, you can do without individual lenses. For example, if a client has a simple prescription (refraction up to 2.0 diopters), no astigmatism, anisometropia and no binocular disorders, a frame with standard parameters and correctly selected base curvature for a specific refraction is selected, he can be provided with high quality vision without aberrations within 30º .

- In the network of optical salons “Glasses for You”, to determine individual parameters of the frame and fit, a measuring ruler from design developers is used (manually), an Impressionist is a video centering device, and a tracer is a device for measuring the frame box system.

Plastics for the production of spectacle lenses

Types of Organic Materials

Currently, organic materials for the production of spectacle lenses dominate the market. From a chemical point of view, these materials can be divided into three groups:

- thermoplastics, which include polycarbonate and polyamides;

- thermosets, which include most traditional plastics, including CR-39 material;

- quasi-thermoplastics or quasi-thermosets, representatives of which are Trivex and Tribrid.

Transparent organic materials were first used to produce spectacle lenses from Motex plastic in 1930. In their design, they were similar to the triplex glazing used in cars - polyvinyl butyral film was clamped between two plates of mineral glass. These lenses were not an industrial success, remaining very fragile, and polymethyl methacrylate (PMMA) lenses appeared in the 1930s and 40s. In the UK, such lenses called “Igard” were produced by pressing by Combined Optical Industries England. In the United States, PMMA lenses are produced by injection molding for the first time. However, lenses made from acrylic polymers cannot gain a significant position in the market due to low scratch resistance, brittleness and the ability to yellow with use.

CR-39

The first industrial success of plastic spectacle lenses was associated with the appearance on the market of the material diethylene glycol bis-allyl carbonate, which was invented by PPG Industries. It was used in aircraft fuel tank windows and reflectors in the 1940s and was patented by PPG Industries in 1946 as CR-39. The first lenses from this material were produced by the American company Armorlite in 1947, and in 1959 the first lenses from CR-39 were produced by Lissac under the brand name ORMA 1000. In the 1960s and 70s, CR-39 began to be used for the industrial production of spectacle lenses companies Sola (Australia) and Silor (France). From then to the present day, it has been the most common material for the production of spectacle lenses, with experts estimating that 70% of these products sold worldwide are made from CR-39.

Organic materials with an average refractive index (1.53–1.59)

These materials appeared in the 1990s from different manufacturers and had different chemical compositions. Lenses made from such materials were popular in Europe before the introduction of organic materials with a higher refractive index, which are now widely used for making lenses in China. Many factories in both Japan and Korea use mixtures of CR-39 and medium refractive index materials to produce lenses (nd 1.55 to 1.56). Depending on the composition, lenses made from this category may or may not withstand the ball drop test.

In 2002, the first spectacle lenses made from Trivex appeared. This transparent polyurethane-based material was originally created by PPG Industries and was used for military applications. Positive characteristics of Trivex: one of the lowest specific gravity values - 1.11 g/cm3, a high Abbe number - in the range of 43-46 (for polycarbonate 29-31), high strength and resistance to shock loads and resistance to solvents. Its refractive index is 1.53.

Organic materials with high and ultra-high refractive index values (1.59–1.76)

The materials of this group were developed by the Japanese company Mitsui Chemicals Inc. to meet market demand for thinner lenses, with the majority being urethane-based thermosets. Materials with a refractive index of 1.60 and higher appeared in the late 1980s. To achieve a higher refractive index, special components are introduced - benzene and sulfur derivatives. As with mineral glass, achieving a high refractive index requires sacrifices in Abbe number and specific gravity. Mitsui Chemicals Inc. is a world leader in the production of highly refractive optical materials for the manufacture of spectacle lenses. Its range includes materials with high and ultra-high refractive index values: MR-8 - a material with well-balanced optical properties and a refractive index of 1.60; MR-7 and MR-10 – materials with a refractive index of 1.67; MR-174 is a material with an ultra-high refractive index, allowing us to produce the thinnest spectacle lenses available today. The company also produces UV+420cut series materials with refractive index values of 1.60; 1.67 and 1.74, cutting off blue light wavelengths up to 420 nm, and MR-8 Plus material with higher impact resistance. Spectacle lenses made from MR series materials are produced by the following companies: Asahi Lite Optical Co., BBGR, Chemiglas Corporation, Daemyung Optical Co., Essilor International, Hanmi Swiss Optical Co., Hoya Corporation, Korea Optical Co., Nikon Essilor Co., Rodenstock, Seiko Optical Products, Shamir Optical Industry, Somo Optical Co., Specialty Lens Corporation, Tokai Optical Co., Younger Optics, Zeiss Vision Care. Currently, sales of materials with a refractive index of 1.67 are growing most rapidly. Lenses made from a material with today's highest refractive index of 1.76 are presented in the Tokai Optical product range. Two more high refractive index materials are discussed below. Polycarbonate is a transparent thermoplastic with a refractive index of 1.59, which has been introduced into the optical industry due to radical improvements in optical properties and uniformity in the production of compact discs and electronics products. The material itself was discovered in 1953 by chemists H. Schnell from Bayer AG (Germany) and DW Fox from General Electric (USA), independently of each other. Polycarbonate lenses were first produced by Gentex Corporation in the early 1980s using injection molding. Convinced of the growing demand for polycarbonate lenses, Essilor acquired Gentex Corporation, a company engaged in their mass production, in 1995. As a result, Essilor became the leading manufacturer of polycarbonate lenses in the world and began to actively promote them in the global optical market. This spectacle lens material is cost competitive with CR-39, yet lenses made from it are lighter and thinner than CR-39 lenses. However, polycarbonate is inferior to CR-39 in optical properties, and it also has one of the lowest Abbe numbers - 29–31. The widespread penetration of lenses made from this material into the US market occurred after the mandatory implementation of strict requirements for the impact resistance of spectacle lenses. Today it is used in the production of lenses for sports, children's, and safety glasses. Tribrid is a material with a refractive index of 1.60, which was created by PPG Industries using hybrid technology based on Trivex and highly refractive materials, which made it possible to combine the advantages of Trivex, such as good optical properties, low weight of lenses made from it, high mechanical strength and resistance to impact loads, and the advantages of highly refractive materials, such as reduced thickness and weight of aesthetically pleasing lenses produced from them. Tribrid lenses appeared on the European market in 2011, and went on sale in the United States in 2013. Today they are represented in the product range of such companies as Thai Optical (Thailand), DAI Optical Industries (Italy), Novacel (France), Shamir Optical Industry (Israel), Seiko Optical Products (Japan), and several others.